Fatigue Heat Build-Up testing module main specifications

The large analysis ranges of the DMA+ series, in term of excitation force, displacement range, and frequency range, associated to MULTITEST software ensure to offer advanced testing conditions capabilities.

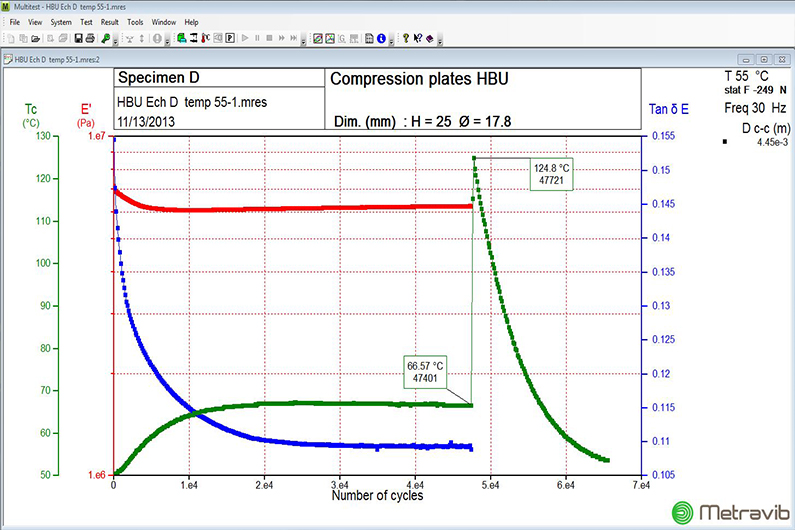

The dedicated Metravib Heat Build Up module specimen holder includes thermally insulated compression plates, a thermal probe measuring the surface temperate at the upper extremity of the specimen and a thermal needle probe pneumatically actioned.

The thermal probe inserted in the upper compression plate, measures the temperature at the specimen surface continuously during the fatigue test. The thermal needle probe is actioned to penetrate inside the specimen at the end of test to obtain an accurate temperature measurement at the heart of specimen without affecting the dynamic test.

Additionally DMA+ series offers many functionalities and capabilities to approach Heat Build Up analysis: tension, shear, with using various specimen geometries as double shear sandwich specimen, rubber sheet, rubber films…

Rubber sheets and films can be tested as well using an optional infrared temperature sensor for measuring the specimen surface temperature.