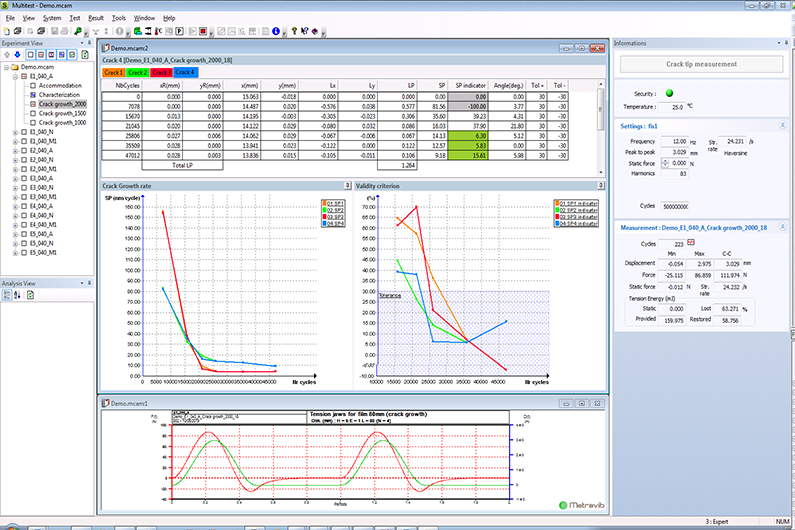

Fatigue crack growth testing module

Advanced tests to measure elastomer cracking

Resistance to fatigue, ageing and crack growth are major issues for rubber like materials.

Current commercial methods for crack growth testing have been restricted to time to failure test.

Since 1999, cooperation with leaders of the Tire industry led Metravib to propose various customized testing machines dedicated to crack growth testing.

Based on this extensive experience, Metravib developed a Fatigue Crack Growth Testing Module to bring to rubber industry and research a quantitative and productive advanced testing instrument.