Shock attenuation and vibration damping

Metravib has been working with major players in aerospace and defense since it was founded in the late 60’s, providing since then unrivaled expertise in engineering and solutions development.

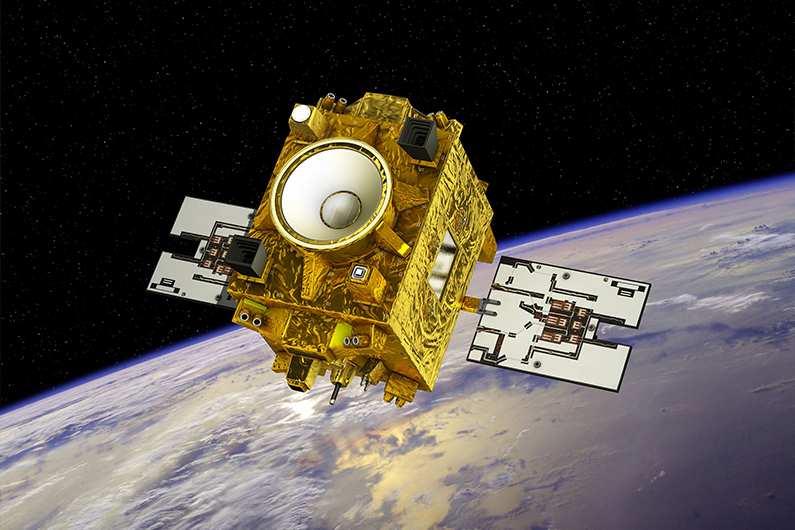

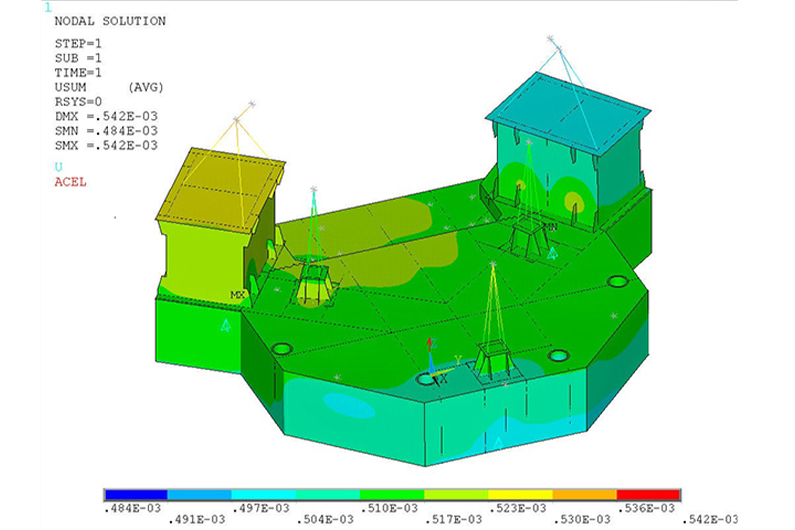

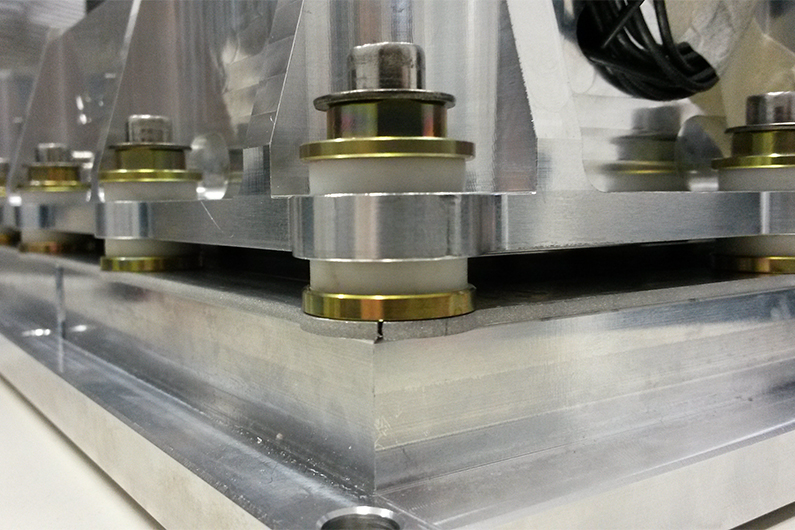

This sector presents numerous technological challenges, such as the need for adequate shock attenuation and protection solutions, the continuous control of vibrations (and even micro-vibrations for observation satellites), of unwanted noise emission (possibly making your system detectable) for acoustic stealth, the need for up-to-date data analysis methods and maintenance tools, including as well the industrialization of composite materials and the qualification of new parts issued from additive manufacturing technologies.

Considering this wide range of applications and issues, Metravib will provide you with expert assistance and field-proven solutions. Health and usage monitoring of critical systems and components, metamaterials applied to lightweighting structures, expert analysis of big data… we are involved with your Engineering teams to define adequate responses tailored to your needs.