The Solution

To define, then produce the relevant pyrotechnic shock attenuation solution, Metravib has developed its own elastomeric materials from existing materials in order to meet the different environmental requirements.

Theoretical calculations were carried out in order to roughly design the elastomer part, checking that the proposed dimensions would ensure the targeted flexibility and meet the stiffness constraints in all directions.

This first theoretical dimensioning was further validated thanks to finite element computations. In parallel, Metravib used its own Dynamic Mechanical Analysis (DMA) machines to characterize the elastomeric part intended for the attenuators.

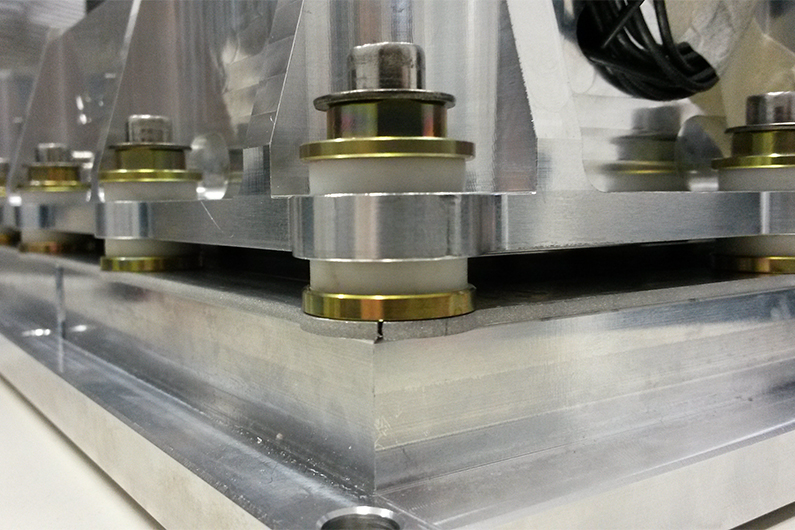

Then, Metravib realized mock-ups and prototypes:

- Manufacturing of elastomer rings

- Manufacturing of mechanical interfaces

- Integration, testing and validation of the corresponding prototypes

before ensuring the serial production.